In this article, I will explain how to connect a Fuelino Proto3 to your motorcycle. Fuelino is a fuel injection controller and data logger designed for motorcycles equipped with EFI (Electronic Fuel Injection). By regulating the fuel injected in the cylinder, you can increase the power of your engine. Even if this modification is optional, if you have a stock engine, it becomes mandatory if you change some components of your motorcycle, such as exhaust pipe, camshaft, cylinder size (bore up kit), air filter and so on. Fuelino helps you to adjust the injection timing, to achieve the proper fuel air ratio which maximizes the output power of the engine, or minimizes fuel consumption. The compensation applied to the original signal timing, in %, depends on the throttle position sensor signal (if connected), and the engine rotation speed (calculated from the measured time period between 2 consecutive "start of injection" events).

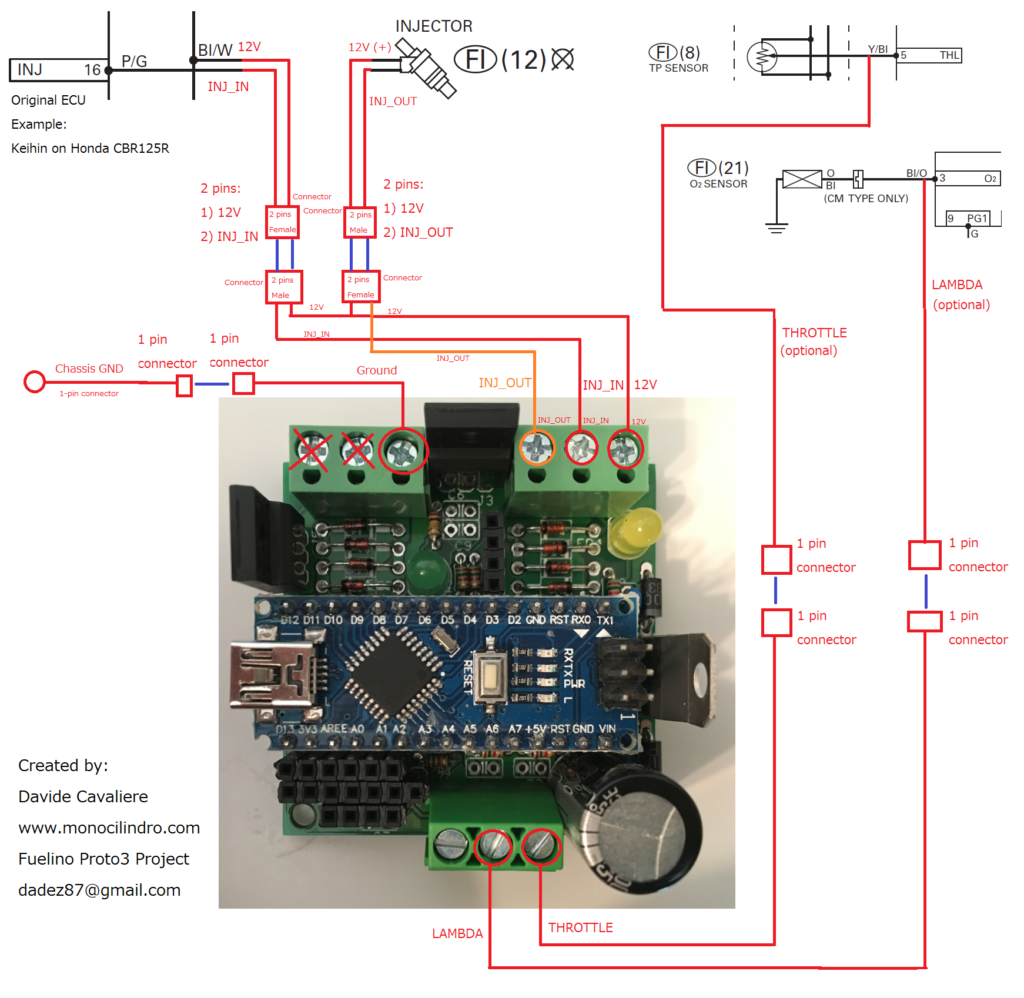

First of all, let's have a look at the wiring diagram. Fuelino is connected as a "man in the middle" between the Original ECU of your motorcycle (example: Keihin on Honda CBR125R), and the fuel injector. In the most simple application, you just need to connect 4 wires:

- Battery voltage, key protected (+12V)

- Chassis ground (0V)

- Injector command input (coming from Original ECU, Fuelino input)

- Injector command output (going to the fuel injector, Fuelino output)

Optionally, Fuelino is able to use, for its control algorithms and data logging operations, additional signals, such as:

- TPS (Throttle Position Sensor) voltage

- Lambda sensor (O2 sensor) voltage

- One additional digital signal (3.3-12V = ON, 0-3.3V = OFF)

The complete installation guide on a Honda CBR125R is available at this link: Fuelino_Proto3_installation_manual_20170114. For other files, please visit the section dedicated to Fuelino. However, Fuelino application is not only limited to Honda CBR125; it can be installed on any other motorcycle equipped with Electronic Fuel Injection (1-2 injectors = 1-2 cylinders), such as: Honda CBR150R, CBR250R, Kawasaki Ninja 250R, D-Tracker, Yamaha R125, R25, Aprilia RS4 125, Piaggio Vespa, KTM Duke 125/250/390, and so on. All you need to do is to check the wiring harness of your motorcycle, in the Service Manual (you can find most of them in Internet, in PDF format), and connect standard cables (you can buy them on local electrical equipment store, or home centers), as shown in the installation manual above. Theoretically, Fuelino HW can support 2 injector inputs (and 2 injector outputs), therefore it is suitable also for motorcycles equipped with 2 cylinders engine. However, at the moment, the latest SW can handle only the interrupts of 1 injector.

The complete installation guide on a Honda CBR125R is available at this link: Fuelino_Proto3_installation_manual_20170114. For other files, please visit the section dedicated to Fuelino. However, Fuelino application is not only limited to Honda CBR125; it can be installed on any other motorcycle equipped with Electronic Fuel Injection (1-2 injectors = 1-2 cylinders), such as: Honda CBR150R, CBR250R, Kawasaki Ninja 250R, D-Tracker, Yamaha R125, R25, Aprilia RS4 125, Piaggio Vespa, KTM Duke 125/250/390, and so on. All you need to do is to check the wiring harness of your motorcycle, in the Service Manual (you can find most of them in Internet, in PDF format), and connect standard cables (you can buy them on local electrical equipment store, or home centers), as shown in the installation manual above. Theoretically, Fuelino HW can support 2 injector inputs (and 2 injector outputs), therefore it is suitable also for motorcycles equipped with 2 cylinders engine. However, at the moment, the latest SW can handle only the interrupts of 1 injector.

If you want to try Fuelino Proto3 on your motorcycle, please contact me (dadez87-at-gmail.com). You can find me also on Facebook, and Linkedin. I can support you very easily, if you have my same motorcycle. On opposite, if you have a different one, I can help you getting the service manual, and in the installation procedure, injection timings calibration, etc. The schematics, Gerber data, Arduino software and so on, are all available to everyone. But if you find problems in manufacturing the board by yourself, please contact me and I can send you a sample, if you help me with the development of this project (Paypal donations are welcome). In case many people are interested in this project, in the future I can consider to sell the samples ("kits to mount", or "already mounted kits") on Ebay, maintaining a cheap price, so that everyone can afford it, even 16 years old young guys who want to install Fuelino on their first motorcycle.

The present Hardware and Software versions are very stable, considering that I tested them a lot, and run many kilometers on my CBR125. Moreover, since the software is Open Source, in case you find any strange behavior, or you simply want to change it a bit to better meet your needs, you can do it freely; then, just re-compile the C/C++ source code with Arduino IDE (or Atmel Studio), and flash it on your Fuelino.

I like your ECU diy. thanks for share

Thank you!

Please find the most recent info and files at the following link:

http://www.monocilindro.com/fuelino/

Thanks to you to have visited this website. Please also visit the page dedicated to Fuelino Project, which has the latest info about software release and so on.

Hello Davide

Very nice DIY device, can it work with other 125 cc Honda ECU like PCX, SH and Forza ?

You are close to build a DIY device working like a Powercommander autotune

Maybe you know that all ready but Honda made a 4v head for CBR 150 sold in India market

Io seguo il tuo lavoro con attenzione

Regards

Generally, it should work with any motorcycle equipping EFI (Electronic Fuel Injection), with 1 or 2 injectors. All you need is to search the Service Manual of your motorcycle, and find the wiring harness diagram, in the part related to the electronic injection. In the most simple configuration, you just need to connect 4 wires: injector + in (12V), injector - in (command input), injector - out (command output), chassis ground (0V).

If you also connect throttle and lambda sensor signals, you can also implement an autotune function based on the value read from the lambda sensor.

The software is capable to acquire ADC signals from throttle and lambda. And it has 2 calibration arrays ("incrementi_thr" and "incrementi_rpm") which define the percentage increment of injection time, based on engine speed and throttle. You can create a function which adapts the values of these 2 arrays, based on the values read from the lambda sensor. The target is to have a lambda sensor voltage around 0.5V, which means the best stoichiometric ratio.

Another function that can be easily implemented are speed limiter.

It's a very interesting work.

Can it modify the ignition curve too ?

I'm not familiar with electronic work, but your tutorials are easy to understand.

May I have your permission to translate some parts of your blog in french and share em on a scooter enthusiast forum ? I can display the topics in private, only for members, if you prefer

Hello, and thank you for your reply.

Yes, of course you can translate the material of this website. My projects are all "open source", therefore feel free to use the contents as you like, but of course since I wrote this content for free, it would be not correct if you copy these contents and use it to make money. But, if you use these contents without the purpose of making money, for me it is fine. 😉 In other words, please keep this project "open source". All hardware and all software is meant to be "open" to everyone, so that everyone can understand how motorcycle electronic fuel injection works, and how to customize it.

Regarding the "ignition", theoretically you can, but it would require a revision of the software. Fuelino hardware has 2 digital inputs and 2 digital outputs. At the moment, on Software side, I am using only 1 input and 1 output to manage 1 injector. But if you modify slightly the software "INJmgr.cpp" and "INJmgr.h", it would be possible to use the 2nd input and 2nd output to manage the ignition.

But the reason why I still did not do that, is that touching the ignition might be very dangerous for the engine. For example, if you make a mistake in the software and you anticipate too much, it might happen that you ignite at a random angle, for example too much in advance, when the piston is still far from the TDC ("top dead center"), therefore there is a risk to destroy the engine (hole on the piston and so on...).

Do you still have some samples for testing ? you can reply on my mail adress if needed

Yes, I still have 1 sample ready. I saw that you sent me an e-mail about your scooter, Honda Forza 125. I replied to you with some PDFs, one is the Honda PCX Service Manual in Vietnamese (sigh), the other is a manual from Malossi which has some pictures showing the location of the injector, lambda sensor, and chassis ground (0V). Basically, same as for my Honda CBR125R, also in your Honda Forza 125, the injector cables should have the same color.

Therefore, you can simply follow the guide in the "Fuelino" section of this website, there is an Installation Manual with pictures, showing the connections which have to be done.

Of course, your scooter is different than my motorcycle. In case of Honda CBR125R, I had to remove the fairings, and move up the gasoline tank, to have access to the throttle body (injector + throttle cables). In your case, I think that you need to remove the seat, because the engine and throttle body is under the seat, in most scooters.

hot to The program by C++ Electronic Fuel Injection ECU? for YAMAHA HONDA SUZUKI KAWASAKI ete. Please tell me .I'm interested in ECU ant tool.

What exactly are you interested into? What do you want to know?

例えばですが、10000rpmでECUからインジェクタコマンド入力がOFFになるECUにFuelino Proto3を割り込ませることによって10000rpm以上の回転数でもインジェクタコマンド出力ができるようには出来ませんか?

It's a very interesting work.

Can it modify the ignition curve too ?

Do you still have some samples for testing ? you can reply on my mail adress if needed

Hello!

Sorry for the late reply. No, it is not possible to change the ignition curve. Only injection.

And unfortunately I don't have other prototypes, because I already sent all of them.

I am very sorry.

Can it be vertical value ignition curve? Thank you Sir

Can it read the value of the ignition angle? Thank you Sir

hallo i'm from indonesia..

your project is very amazing..

but for makw it simple.. can we set the incresment with a potensio or variabel resistor? and can we use a lcd to show the percentage of incresment?

Yes, for sure it is feasible, but you need to modify the software so that you can use one of the analog inputs of the Arduino to read the voltage on a potentiometer. If you have time and want to modify the Software, it is feasible for sure.

Hi Davide,

I'm Jeffrey, and i have a couple of questions for you.

How does it exactly work, because i can't figure out where the 12v of the injector is coming from.

I see how you process the injector input, but how do you control the output to the injector itself?

Best Wishes, Jeffrey.